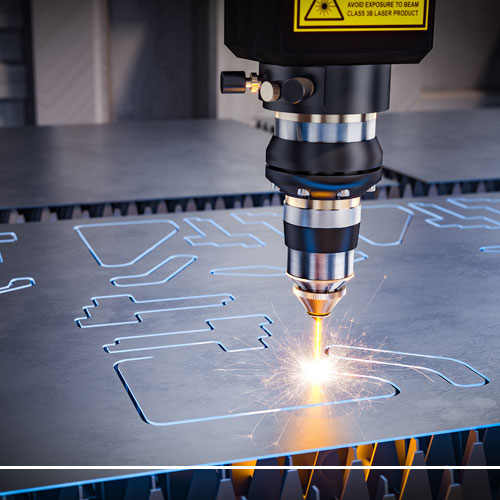

LASERS

Our fiber lasers offer extreme accuracy and cost efficiency on a wide range of materials. Sheet sizes up to 60” wide can be cut with optimal nesting programs for greater material yields. Automated sheet loading/unloading provides greater efficiency and increased production capacity.

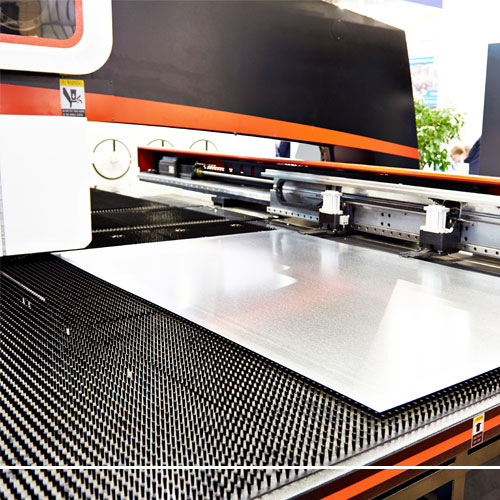

TURRET PRESSES

Our CNC turret presses are ideal for punching numerous holes in parts up to 1,000 hits per minute and can also accommodate sheet sizes up to 60” wide. Additionally, these machines have forming capabilities for such shapes as louvers, knock-outs, off-sets, stiffening ribs, and number and letter stamps.

METAL CUTTING

Whether it is with our CNC power band saws, power hacksaw, or the ironworker, we can cut your bar stock, angle, channel, or tubing within very strict tolerances.

PRESS BRAKES

Forming operations are performed on CNC press brakes for bends up to 14’ at 187 tons. The press brakes are equipped with a CNC 8-axis programmable back gaging system to assure part accuracy and repeatability.

WELDING

We use a variety of welding processes including MIG, TIG, flux core, spot welding, and weld guns to satisfy any customer requirement.

INSERTION PRESSES

Our automatic self-feeding insertion presses can assemble or install self-clinching fasteners (nuts, studs, standoffs) into your sheet metal parts.

When your project has been fabricated, what comes next?

Find out more about our: